For logistics service providers, production material supply is a complex and resource-intensive process that requires continuous optimization. Our development for one of our clients aimed to accelerate and simplify the SAP system's transport order confirmation and delivery note creation processes. Let's take a closer look at the initial state and the implemented solution!

Initial State and Challenges

The process involves supplying production from an external warehouse, handling 6,000–8,000 boxes per shift. Currently, this is carried out by 4-5 employees as follows:

- Demand Collection and Label Printing – Data is aggregated twice per hour, and storage labels are printed within the SAP Logistic Execution Warehouse Management system.

- Material Identification and Picking – Employees scan the source storage bin, unique packaging unit labels, and then place the boxes on picking carts.

- Verification and Final Pre-Shipping Check Process – This scanning step ensure that all picked materials are properly confirmed in SAP.

- Delivery Note Creation Process – Another scanning cycle is performed to generate the delivery note.

The process was time-consuming because each box had to be scanned at least three times, leading to 36,000 daily scans. This consumed significant human resources and increased the risk of errors.

The Solution: Automated Scanning and Confirmation Process

The goal of the development was to reduce manual work, accelerate confirmation, and simplify delivery note creation in SAP. Since internal SAP development was not an option, we implemented an external interface-based solution:

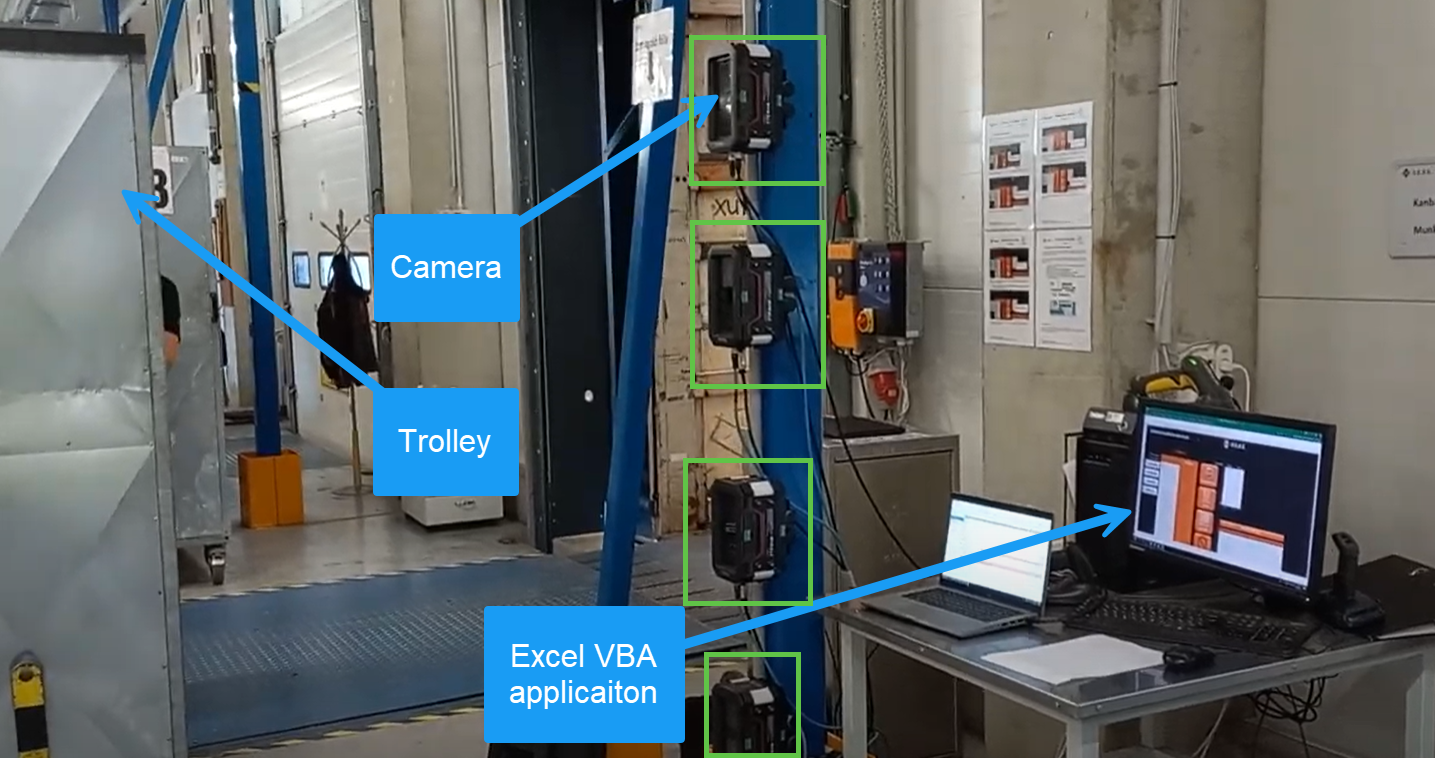

- Excel-Based Data Processing with VBA Macro – The Excel-based solution receives and sends data through SAP interfaces and print picking label in the right order to optimize pick path.

- Automated Camera-Based Scanning – High-resolution cameras were installed in the staging area, automatically capturing barcodes on all boxes on picking carts.

- Data Verification and Confirmation – A VBA script in Excel retrieves the relevant transport orders and handling units from SAP, then automatically performs verification and confirmation.

- Delivery Note Generation – After data aggregation and SAP interface processing, the delivery note is automatically created and printed as needed.

Results and Efficiency Gains

The new system delivered significant savings:

- Daily manual scanning was reduced from 36,000 to just 6000.

- Labor demand decreased by nearly 30%.

- Errors were minimized due to automated verification.

- The delivery note creation process was completely transformed, making it faster and simpler.

Conclusion

This development is a great example of how leveraging SAP standard interfaces and simple automation tools (Excel VBA + camera system) can achieve significant process optimization. The results show that a well-designed digital solution can enhance logistics processes, reduce manual work, and improve data accuracy.